USE YOUR EXISTING NETWORK ARCHITECTURE

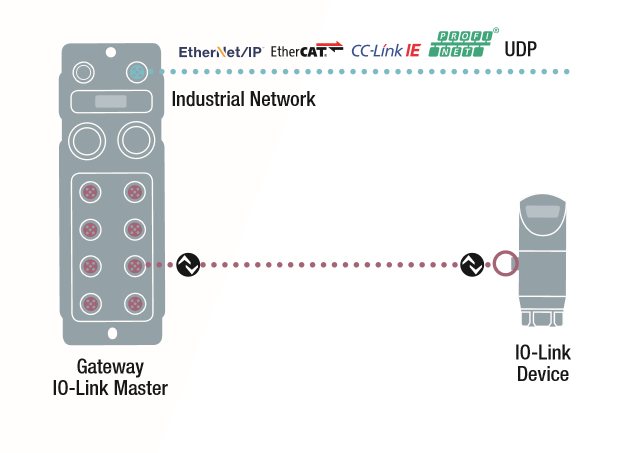

IO-Link technology utilizes your existing network infrastructure addressing is point-to-point with a master/ device relationship.

Features

- Similar to USB architectures

- Typically one device per master port

- All major PLCs and industrial networks supported

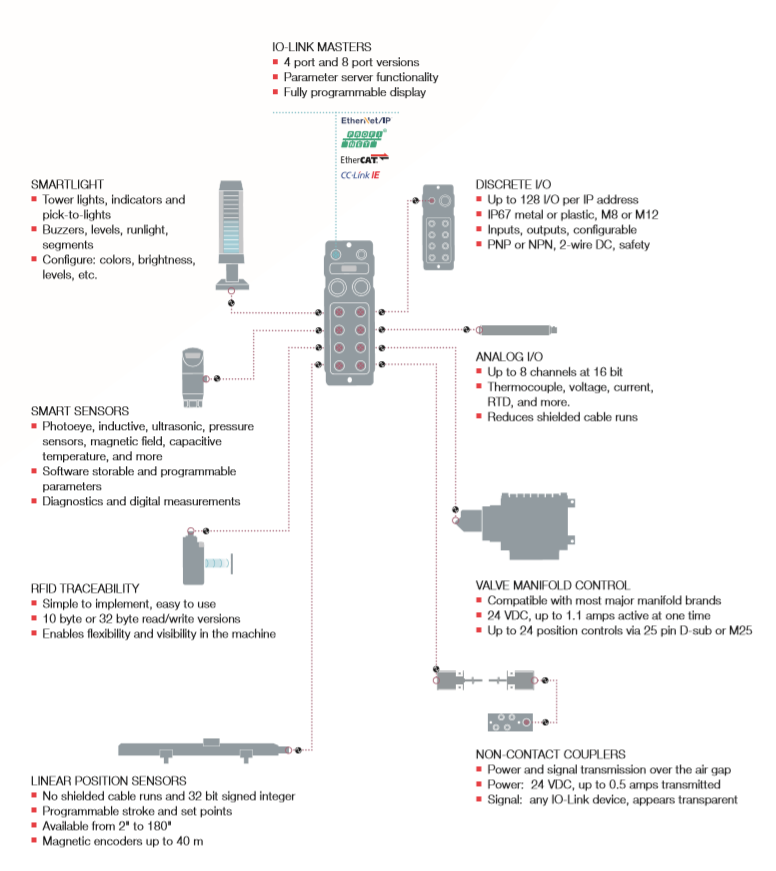

From stack lights to solenoid valves to proxes to measurement devices, a variety of inputs and outputs are required to make a production line run and flexibly operate. IP20 slice style solutions require a collection of other products like terminals, circuit breakers and control cabinets. By utilizing IO-Link, a machine can have dramatically reduced wiring, smaller electrical cabinets and provide diagnostics that allow for quick troubleshooting of I/O problems.

Features

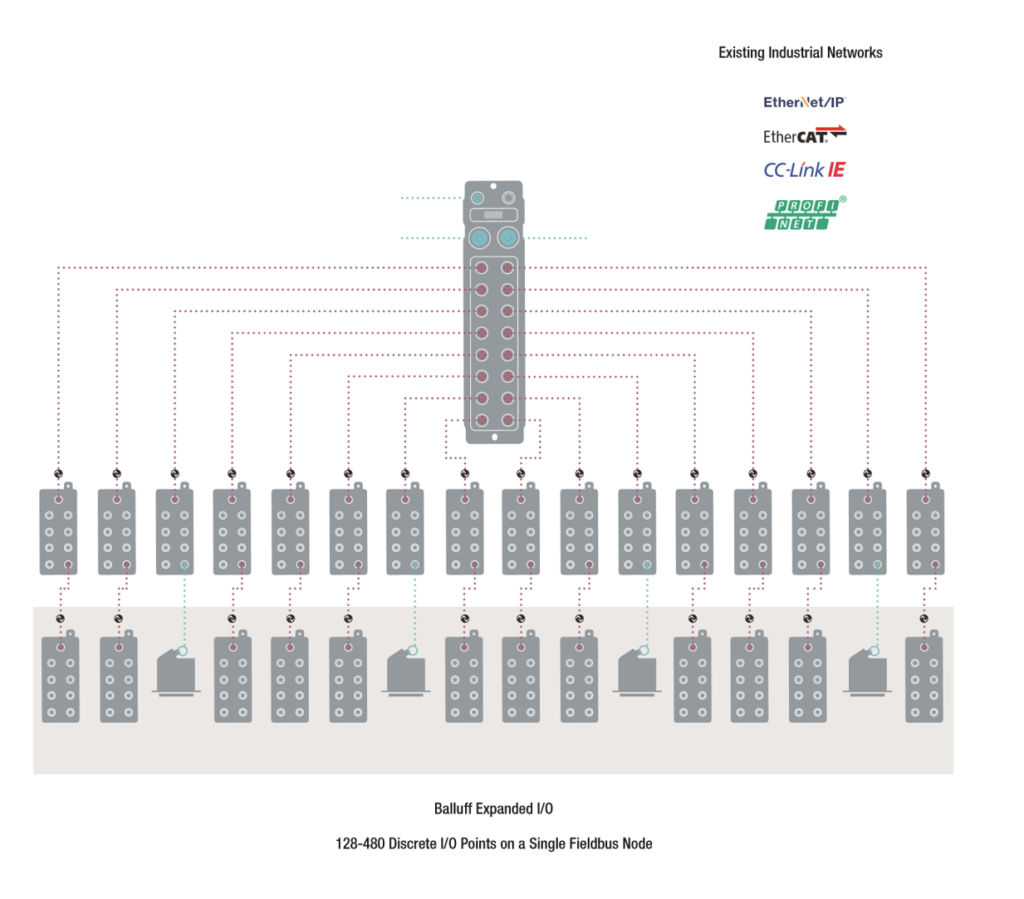

- Use existing equipment infrastructure and networks

- IO-Link masters are available with 4, 8, and 16 ports

- Discrete I/O, analog I/O, valve manifold control

- Any vendor’s IO-Link device can be utilized

TROUBLESHOOT FASTER AND REDUCE DOWNTIME

Time is a valuable resource. Maintenance crews and operators need to quickly find a solution to a problem and get the equipment running. By implementing IP67 machine mount I/O, the failed points become more visible and accessible. In addition, diagnostics provided by the individual intelligent devices can help narrow the scope of the problem and speed recovery. Operators can provide technicians exact details of the failure and time can be saved for the technician by knowing and preparing for the problem before they even arrive at the equipment.

ELIMINATE ANALOG HEADACHES

When using analog devices on a machine it can be difficult to find a path for the shielded cable that does not incur noise from motors or other complications. By utilizing IO-Link, the analog to digital conversion is done inside the device, and then a standard sensor cable can be used for the connection, providing feedback noise – free. In addition, the smart device reports engineering units (mm, PSI,°C) which reduces the effort to program and integrate.

KEEP VALVE MANIFOLDS SIMPLE

Trying to find a short in or replacing and rewiring a 25 conductor cable run can be time consuming and costly. By implementing valve manifold connectors with IO-Link integrated into them, the wiring of the valve is dramatically reduced and taking the installation from 25 termination to a simple M12 connector makes it quick to repair. In addition, the valve manifold controller with IO-Link can provide basic diagnostic information for troubleshooting any issues on the equipment quickly.